I have received quite a few questions from clients about the status of the 179d tax deduction and when we could expect it to be extended. The short answer is that no formal action has yet been taken beyond some bills being introduced in the house and all of them are still sitting in committee.

Based on my conversations with legislators, they did not expect for extension legislation to be taken up until after the new federal budget had been approved. Even after that, I won’t be surprised if other high-profile legislation (i.e. healthcare) cuts in line and gets the attention of Congress first.

If you aren’t familiar with the 179d tax deduction, it was established by the federal Energy Policy Act of 2005 and is for energy-efficient commercial buildings placed in service from January 1, 2006, through December 31, 2016. Throughout the years, it has expired and been renewed multiple times with bipartisan support. The deduction is available primarily to building owners, although tenants may be eligible if they make construction expenditures and own the new equipment for tax purposes.

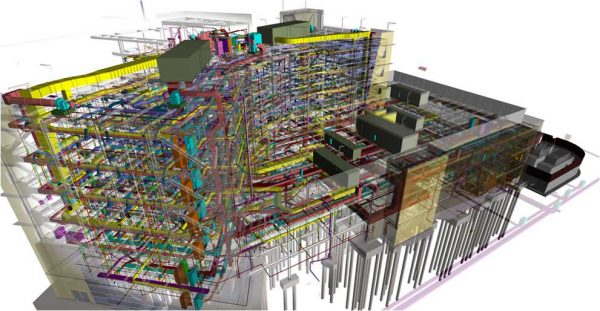

The tax deduction of $1.80 per square foot is available to owners of new or existing buildings who install (1) interior lighting; (2) building envelope, or (3) heating, cooling, ventilation, or hot water systems that reduce the building’s total energy and power cost by 50% or more in comparison to a set baseline. Partial deductions of $0.60 per square foot are available for buildings that do not meet the 50% threshold, but individual systems provide sufficient savings to justify certification (25% for lighting, 15% for HVAC and 10% for the envelope). The deduction may not be more than the capitalized cost of the installed systems (this generally includes the cost of labor and may include recycling costs).

It’s not too late to certify properties that were completed or renovated prior to expiration. In fact, properties can be certified all the way back to January 1, 2006 as long as you are willing to amend taxes from the year the project was completed. If you have a building that may be a good fit for the deduction, please contact us and we’ll be happy to look at it with you. We will continue watching the progress of the 179d extension and put any updates we hear about here on our site.