Air conditioning and heating equipment is rated by manufacturer’s to give the consumer an idea of how efficient it is. Typically calculated by comparing the energy input versus the energy output, it allows consumers to compare similar equipment. But what exactly do these numbers mean and how do they relate to actual costs?

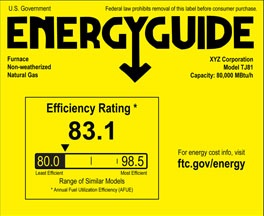

For heating, the calculations are generally quite simple. A natural gas furnace that puts out 104,000 Btu/hr in heat but requires 130,000 Btu/hr to do so would be rated at 80%. The missing 26,000 Btu/hr are lost up the chimney. How does this translate to actual costs? The national average cost of natural gas in 2015 was approximately $0.80 per therm (aka 100,000 Btu). For every hour your furnace is on, you pay $1.04 to get $0.83 worth of heating (a loss of $0.21 per hour). Let’s say the same furnace was rated 94%. Now you only pay $0.89 for the same amount of heat (a loss of only $0.06 per hour). If our example building was in Arkansas, these savings could add up to about $200 per year for this size of furnace.

On the air conditioning side, the equipment works very differently and requires an alternate approach. Air conditioners are called heat pumps because they pump the heat out of your home or business. The efficiency is shown using the Energy Efficiency Ratio (EER) which is a ratio of output cooling energy (in Btu) to input electrical energy (in Wh). For example, a unit with an EER of 12 would require 5 kWh to move 60,000 Btu (aka 5 tons). To translate this to costs, the 5 ton unit requires $0.52 to operate for one hour (based on 2015 national average of 10.42 cents/kWh). The same unit with an EER of 16 would only cost $0.39 cents per hour. Continuing our example, if this unit was on a typical building in Arkansas the savings between 12 and 16 EER could be around $600 per year.

The trick with energy efficiency is to balance the cost savings from usage (like we calculated above) with the initial cost of the equipment, available incentives, project location, building type and usage. These are all major factors and we engineers often use computer simulations to help us in calculating the savings. If you think your building could use some energy upgrades, please consider hiring us to take an in-depth look and determine how you can lower your costs by saving energy.