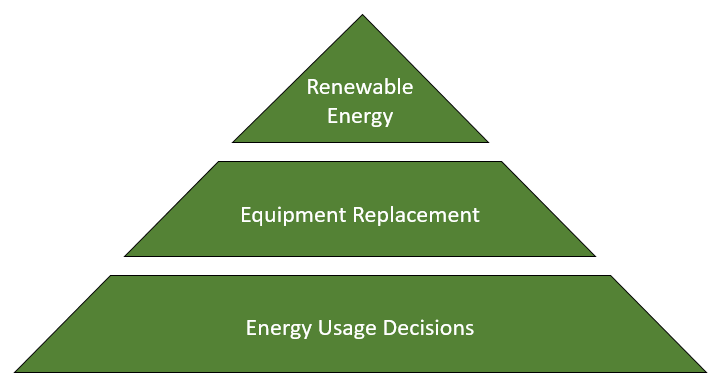

So you want to reduce your building costs? From thermostat setbacks, equipment replacements and renewable installations there are many ways to save energy. But where do you start? One of the main guides we use in making energy efficiency recommendations is something called the Energy Efficiency Triangle. A google search shows that there are quite a few variations of it, but they generally follow the same structure.

At the bottom of the triangle are improvements that have low capital cost and usually deal with a building’s “culture.” Examples would include turning off lights when a room isn’t in use, setting the thermostat to have setbacks during unoccupied times and determining start up times for equipment if peak demand charges are in place.

The next layer of the triangle looks at equipment replacements. These measures will usually have a capital investment, but calculations can be done to determine the payback period. Examples of this category are replacing lighting fixtures with LED equivalents, replacing HVAC equipment with higher efficient units and adding insulation to exterior walls or roofs.

The peak of the pyramid is where you find renewable options. The reason these are at the top is you want to avoid installing a nice renewable system only to generate power you don’t really need. In short, once you’ve reduced your usage as far as it can go, you can then look at generating the remaining power on site.

If you are interested in applying these principles to your building, please contact us. We would love the opportunity to look at your building and help you make energy efficient decisions that reduce your energy costs.